“That’s one small step for man, one giant leap for mankind.” – Neil Armstrong

July 20, 1969. Neil Armstrong and Edwin “Buzz” Aldrin became the first humans to ever set foot on the moon. But it almost didn’t happen and it almost ended in tragedy. As the Apollo 11 Lunar Excursion Module (LEM) was preparing to land on the moon, the onboard navigational computer started flashing a “1202” alarm. The crew had been meticulously following their checklist. Each step, nominal. But now, something was wrong. Abort? As the crew radioed in the situation to mission control, they could feel the adrenaline surge and anxiety rise.

For months, the crew, the nation and the world were anticipating this historic moment. It was one of the most heavily covered and widely watched events in history. An estimated 600 million people were watching worldwide. The mission had captured the imagination of people. Now, all of it was in jeopardy. “1202” alarm! The alarms kept going off. Each time the LEM guidance computer flashed that alarm, it would reboot and restart. Not good! I can almost feel that tension myself. This was a critical stage that would demand precision to guarantee the safe landing of the module on the treacherous moon’s surface below. Sounds like bad news, right? Would this require the mission to abort?

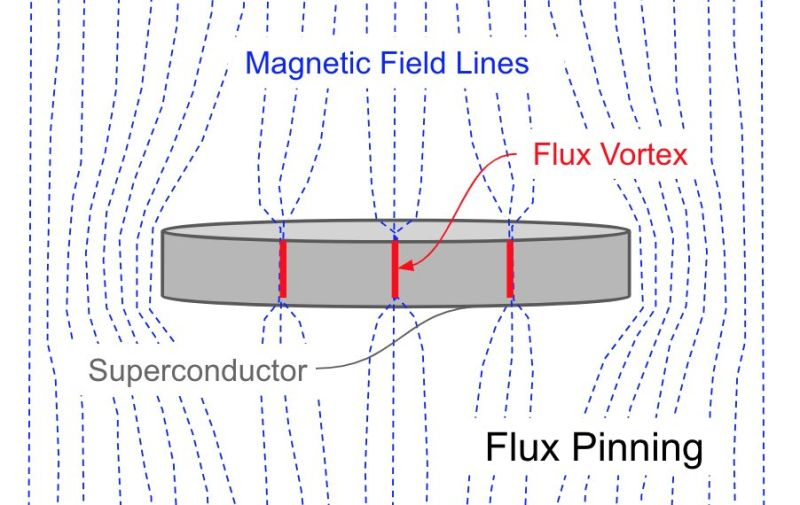

With millions of people, sitting on the edge of their seats, Mission Control finally responded. The mission would proceed. Relief! It turns out that this was a “known error” that NASA had seen many times before during simulation testing. The computer had a capacity of 2KB erasable memory and 16KB of fixed memory. The computer would run several concurrent programs related to navigation, all competing for the limited memory. If a program couldn’t allocate memory, the “1202” alarm would be raised and the system would reboot. At restart, the most important programs would start up again where they left off. Thankfully, the mission would proceed. Neil Armstrong would soon step off of the LEM and millions of people would hear him say those “one small step” historic words.

But the mission wasn’t over. The mission was to get them safely home as well. Unfortunately, while the astronauts were suiting up for their moon walk, they accidentally bumped into the button of a circuit breaker. It broke off. This switch controlled the power running the ascent engine, the one responsible for getting them off of the moon. Unless it could be fixed, they would be stranded on the moon. NASA and US President Nixon were preparing for the worse, drafting speeches to be given when their oxygen supply ran out. Thankfully, it wouldn’t be needed. Mission control didn’t have a solution, but Buzz Aldrin did. His background in mechanical engineering paid off! He looked at the small opening where the circuit breaker had been and realized he could manage to depress the breaker with a small felt-tip marker. He did and it worked! Mission control reported the circuit was closed. In my mind’s eye, I can’t help but play out that scenario. I imagine Buzz pushing in that pen and saying with confidence, “To Infinity and Beyond!”

Problems always happen. It isn’t a matter of “if” but “when”. What do we do to prepare for them? What do we do when they happen? The story above reminds me of the importance of preparation. The “1202” alarm could have killed the mission, but it didn’t because NASA had invested in time to play through the simulation many times. Seeing this exact alarm gave them confidence in the LEM computer’s ability to recover from this condition. Testing is important, not just to prove that something is ready for launch, but to build knowledge. The testing didn’t remove the alert, but gave the mission team a foundation of experience to make difficult decisions in the heat of the moment.

Not every possible condition can be tested or will be discovered during simulation. As the circuit breaker example highlights, creative problem solving is still needed. The Apollo mission is full of stories like this, but it isn’t alone. We need engineers. We need smart creatives who are capable of plotting solutions across seemingly impossible odds.

Hopefully you won’t find yourself stranded on the moon anytime soon, but I bet you could be running simulations for learning or plotting solutions to problems. You are engineers. You are creatives. You are critical to the mission! Thanks for all you do in helping making the impossible, possible, every day.

To infinity and beyond!

References

- Inspired by the Apollo 11 story as referenced in this book:

Kim, Gene, and Steven J. Spear. 2023. “Wiring the Winning Organization: Liberating Our Collective Greatness through Slowification, Simplification, and Amplification.” IT Revolution, Portland, OR. [Link to the book: https://itrevolution.com/product/wiring-the-winning-organization/] - Apollo 11 Program Alarms – NASA – https://history.nasa.gov/alsj/a11/a11.1201-pa.html

- The Untold Story – What Went Wrong on Apollo 11’s Moon Landing? A Lot More Than You’ve Been Told – https://apogeerockets.com/education/downloads/Newsletter276.pdf

- These 6 Accidents Nearly Derailed Apollo 11’s Mission to the Moon – https://www.livescience.com/65975-apollo-11-accidents.html

Images

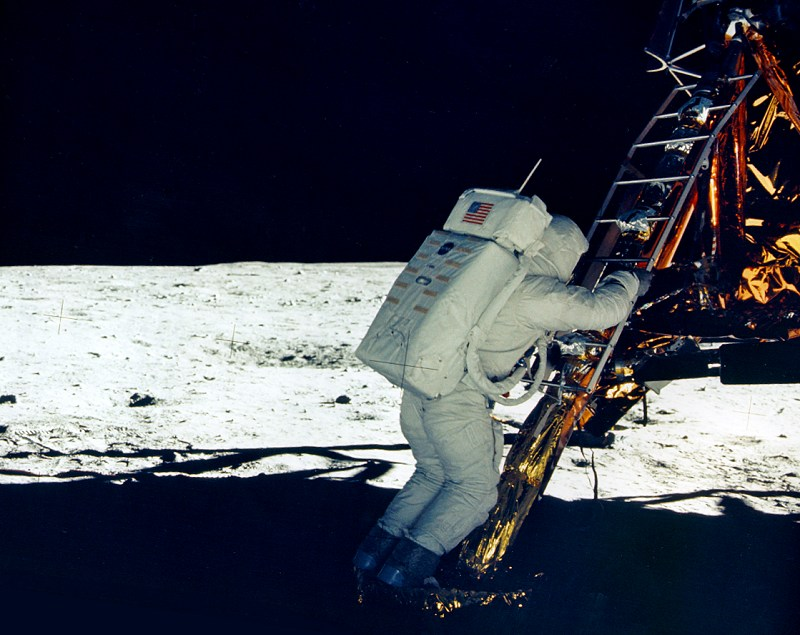

- NASA – Aldrin on the LM footpad

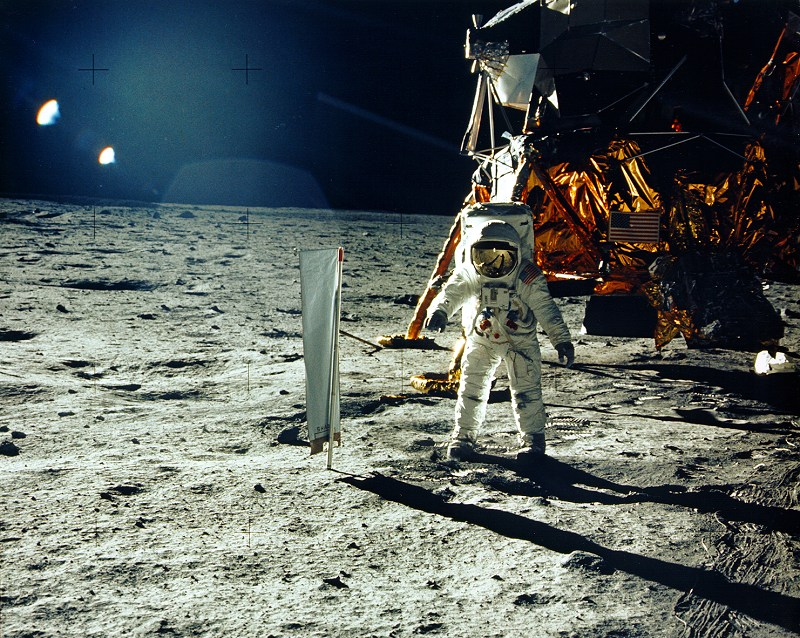

https://history.nasa.gov/ap11ann/kippsphotos/5869.jpg - NASA – Aldrin beside solar wind experiment https://history.nasa.gov/ap11ann/kippsphotos/5873.jpg